Multihog MH

One machine, one driver, endless applications.

Overview

This proven solution and award-winning machine is the most popular Multihog model in the UK used by over a third of all local authorities and most major airports.

120 litres per minute of hydraulic flow and an ultra-efficient 75HP engine as well as same track pivot steer provides the perfect combination of power and compact design.

-

Width

1960 mm

-

Height

2400 mm

-

Length

3400 mm

-

Unladen Weight

3290kg

-

Engine

75HP Kohler, Diesel (Tier IV Final)

-

Gross Weight

6000kg

-

Max Hydraulic Flow

120 litres per minute

-

PTO

Load-sensing hydraulics front and rear

-

Drive

Patented ‘sure drive’ 4-wheel drive (2 stage differential lock)

-

Operating License

Standard UK DVLA Driving License

-

Road Registered Speed

40 kph

-

Turning Circle

3000mm

-

ROAD READY

Every Multihog machine is road legal and can safely and speedily travel on the highway up to 40km/ph to reduce additional vehicle transport costs and every machine can tow.

-

MAXIMUM MANOEUVRABILITY

Every Multihog is designed to access difficult and different environments with ease as a result of the articulation. Most model’s same track pivot steer means the rear tyres follow the same path of the front.

-

ROBUST BUILD

Rust is a must not – each Multihog’s steelwork is powder coated and salt spray tested for 2000 hours to guarantee longevity. Unlike other manufacturers, all Multihogs are built in Western Europe and use quality components to reflect this.

-

POWERFUL AND EFFICIENT

No ad-blue needed – all Multihogs are already fitted with ultra-efficient engines (Tier IV Final) regardless of size and equally every machine can pack a punch of between 90-120 litres hydraulic flow per minute.

-

UNRIVALLED ADAPTABILITY

Designed to eliminate downtime, switching between different attachments on the front or back only takes a couple of minutes due to the quick release mechanism requiring no manual or mechanical work.

-

EMPOWERING OPERATORS

When an operator takes control of a Multihog they become a master of whatever application they undertake due to the comfort and familiarity of controls aided by 360° visibility, push and go drive and simple ergonomic joystick operation.

-

PATCH PLANER

300 – 600 planing width

-

DE-ICER

1200 litre

-

salt spreader

1.0m³ capacity

-

snow blower

1.2 – 2.4m

-

Snow brush

2.0m

-

flail arm

4.45m reach | 1.0 or 1.3m width cutting head

-

Flail Mower

1.2 – 2.2m width

-

rotary mower

1.5 – 4.0m width

-

cylinder mower

3.3 – 4.4m width

-

high pressure washer

220 bar | 850mm wide spray bar

-

weed brush

90cm brush diameter

-

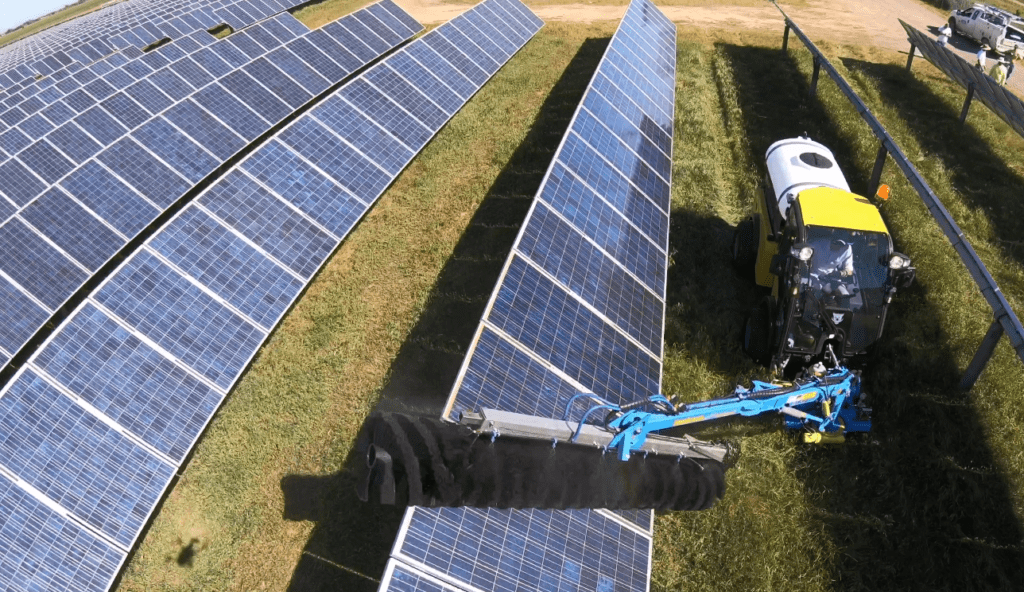

solar panel cleaner

4.5m – 7.0m reach

-

SNOW PLOUGH

2.6m +

REDEFINING WHAT’S POSSIBLE

Versatile range of applications

Established in 2008, the Multihog product has evolved and expanded through continuous innovation due to our close customer collaboration and success.

Take a closer look

EXCEEDS EXPECTATIONS

“Utilising the Multihog is very fast, it’s efficient, it’s cost-effective, it reduces health and safety risk of HAVS exposure to our teams.”

Andy Wilde | Director of Infrastructure

Shropshire Council

COMPARE MODELS

Explore the Multihog range

The Multihog model range ranges from small all-rounders to high-performance all-rounders.

Attachments

The Multihog MH has been specifically developed as an implement carrier. The Multihog has many specific attachments, which are plain to see as it goes about its daily work.

SETTING THE STANDARD

Latest case studies

We’re dedicated to doing more for less, more efficiently and productively than the accepted standard.

GET IN TOUCH

Contact us today

We are fully committed to providing first class service and support to the industries we work with. Our sales and technical teams are trained and experienced, with comprehensive product and industry knowledge.

Let us know how we can help by filling in the form, and one of the team will be back in touch.

Call our team: (+44)1254 703 212

Interested in joining the team?

Take a look at our careers page to see what opportunities are currently available or find out how to express an interest in working with us.